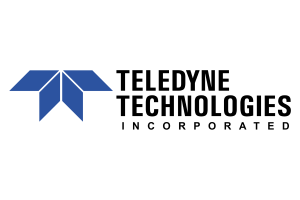

Producing Industrial Plastic Parts of Unparalleled Quality

Whether they are engineers requiring custom pulleys or medical institutions needing specialized medical devices, clients rely on I.F. Associates for innovative products and quality components.

Services We Offer

- Design, Engineering, and Prototyping: We offer comprehensive services including designing, engineering, and prototyping. Whether you have existing conceptual drawings, CAD files, or simply rough ideas, our team of experienced industrial engineers can assist you throughout the process. We ensure accurate prototypes that match your final product specifications.

- Industrial Design and Engineering: Our experienced team assists in designing and engineering your products, ensuring they meet your requirements and specifications.

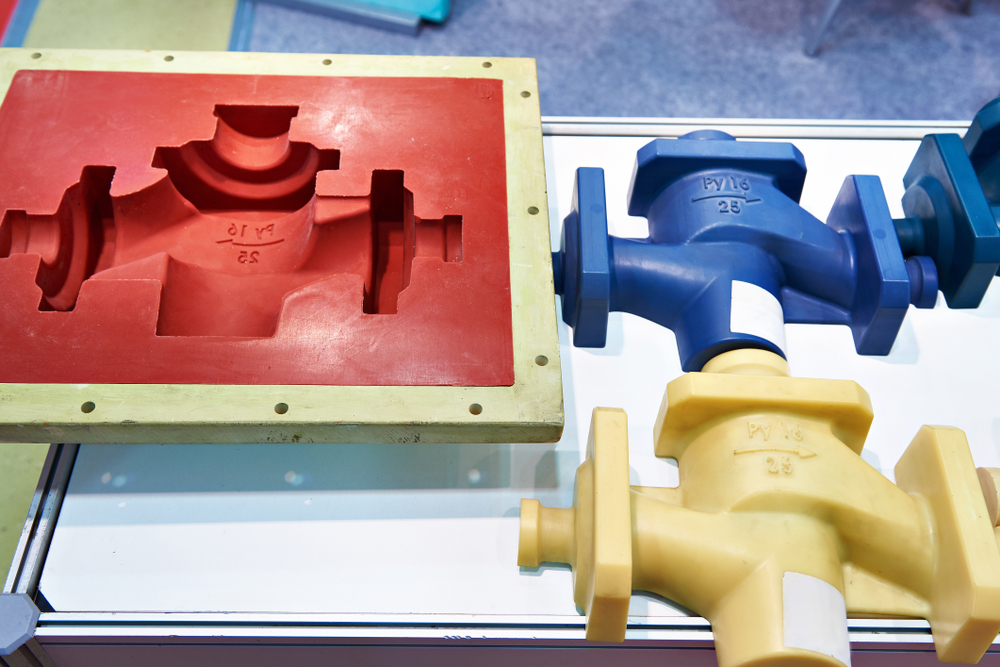

- Complex Tooling: We handle industrial complex tooling efficiently to meet the demands of your project.

- Plastic Injection Molding: With expertise in plastic injection molding, we cater to orders of all sizes, from small to large, and varying durations.

Why You Should Partner with

I.F. Associates

- Pump and fluid handling systems

- Vacuum system components

- Conveyor components and assemblies

- Controls and packaging

- Valves and fitments

- Experience: With over four decades of experience since our establishment in 1977, I.F. Associates has a proven track record of delivering quality products and satisfying our customers’ needs.

- Trust: Our commitment to quality and customer satisfaction is unwavering. We work closely with our clients to ensure their goals are achieved.

- Capacity: Equipped with state-of-the-art machinery and expertise, I.F. Associates can accommodate various orders, from short runs of tiny plastic parts to large orders of complex parts.

Ensuring Reliability: Why Quality of Industrial Plastic Parts Matters

| Part Type | Specific Part | General Specifications |

|---|---|---|

| Pump and Fluid Handling Systems | Impeller | Material: Chemically resistant plastics like PVC, PP, or PVDF are advised |

| Vacuum Manifold | Vacuum System Components |

Material: Durable plastics such as ABS or polycarbonate are recommended |

| Conveyor Components and Assemblies | Conveyor Belt |

Material: Wear-resistant plastics like nylon or UHMW |

| Controls and Packaging Handling Systems | Control Panel Housing |

Material: Food-grade or industrial-grade plastics |

| Valves and Fitments | Ball Valve | Material: Chemically resistant plastics such as PVC, PP, or PTFE are recommended |

Diverse Clients Trust I.F. Associates