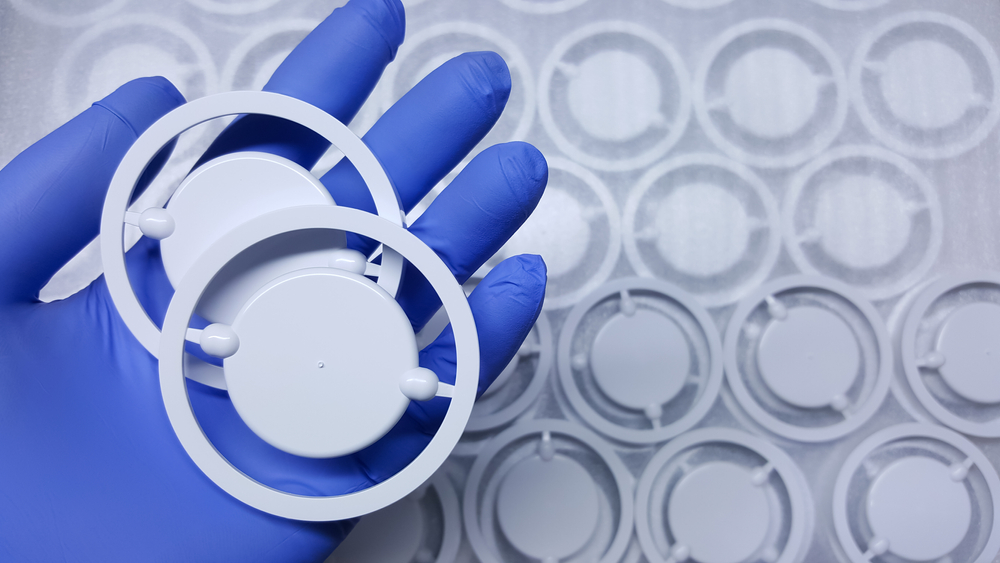

Plastic Injection Molding Company: Assembly and Sub-Assembly Process

I.F. Associates specializes in the efficient injection mold assembly and production of various products, leveraging custom molding techniques and precision parts to ensure high-quality outcomes. Our services are designed to offer numerous benefits to our clients, including streamlined manufacturing processes, superior product quality, and tailored solutions to meet specific requirements.

- Assembly: This refers to the process of putting together various components to create a finished product. It usually involves multiple parts coming together to form the final product.

- Sub-Assembly: Sub-assembly involves assembling smaller components or groups of components that will later be combined with other sub-assemblies to form the final product. Sub-assemblies are smaller, partial assemblies later integrated into the larger assembly process.

Step-by-Step Process

Imagine a plastic injection molding company that produces plastic enclosures for electronic devices. These enclosures may consist of multiple components such as the main housing, buttons, screws, and electronic connectors. Here’s how the assembly process might unfold:

- Injection Molding: The company starts by injection molding the various plastic components.

- Assembly: Depending on specifications, skilled manual operators or automated machinery assemble the parts to form the enclosure. This process involves fitting the buttons into their respective slots, securing the screws, and attaching the electronic connectors.

- Sub-Assembly: Certain components may be grouped together as sub-assemblies before final assembly. For example, the buttons and their corresponding mechanisms might be assembled separately before being integrated into the main housing.

- Final Assembly: The sub-assemblies are then combined with any remaining components to complete the finished product.

Understanding Manual, Semi- and Fully-Automated Assembly

No matter the complexity or scale of your project, I.F. Associates is committed to delivering flawless assembly solutions that meet your timeline, budget, and quality standards. We are fully equipped with skilled manual operators, and we can also provide semi or fully-automated assembly of small, medium, or large quantity lots.

- Skilled Manual Operators: For projects that demand hands-on precision and attention to detail, skilled manual operators have the skill and expertise to handle delicate parts or adjust assembly processes on the fly.

- Semi-Automated Assembly: Semi-automated assembly involves a combination of manual labor and machinery. Certain tasks may be automated to improve efficiency, while others require human intervention for more complex or variable processes.

- Fully-Automated Assembly: In fully-automated assembly, machinery handles the entire process with minimal human intervention. This process is suitable for tasks with high repeatability and consistency.

Benefits of Each Assembly Option

The choice between manual, semi-automated, and fully automated assembly depends on factors such as the complexity of the task, desired precision, and scalability requirements.

| Aspect | Manual Operator | Semi-Automated Assembly | Fully Automated Assembly |

|---|---|---|---|

| Precision | High | High | Very High |

| Flexibility | High | Moderate | Low |

| Setup Time | Moderate | Moderate | High |

| Scalability | Limited | Moderate | High |

| Complexity of Operations | Can handle complex tasks with ease | Can handle moderately complex tasks | Best suited for simple, repetitive tasks |

Why You Should Partner with

I.F. Associates

With a dedication to detail and flexibility, our company specializes in injection molding tailored to your specifications. Whether you require short runs or large quantities of precision parts, we offer manufacturing and assembly services with full inspection capability.

Our commitment to excellence, demonstrated through our high-quality plastic injection molding services and extensive experience with various engineering resins and thermoplastic elastomers, makes us an invaluable partner in your product development journey.

- Rapid, low-cost tooling and parts

- Short-run and bridge production capabilities

- Dedication to detail and flexibility for fast and accurate service

- Ability to mold from a few pieces to many thousand pieces with prototype tooling

- Comprehensive First Article Inspection Reports provided

- A wide range of engineering resins and thermoplastic elastomers processed

- Expertise in Sonic Welding, Molded-In, and Press-In Inserts for versatile assembly options

- Labeling and packaging

- Full inspection capability for ensuring precision and quality in every part

- Excellent references and invaluable experiences to support your product development efforts

Custom Injection Molding Since 1977

At I.F. Associates, custom molding isn’t just a service – it’s our specialty. We prioritize building close working relationships with each client, ensuring we understand and meet your unique design-to-production challenges. Our pride lies in our ability to engineer high-quality injection-molded plastic parts to your specifications.

We handle products made from various thermoplastic resins, engineering-grade resins, and elastomeric materials. Our expertise lies in custom injection molding, where we excel in achieving tight tolerances and accommodating unusual configurations. We also offer injection mold assembly as a part of our services. Quality assurance is paramount, with our standards ranking among the highest in the industry.

Diverse Clients Trust I.F. Associates

Have a Project In Mind?