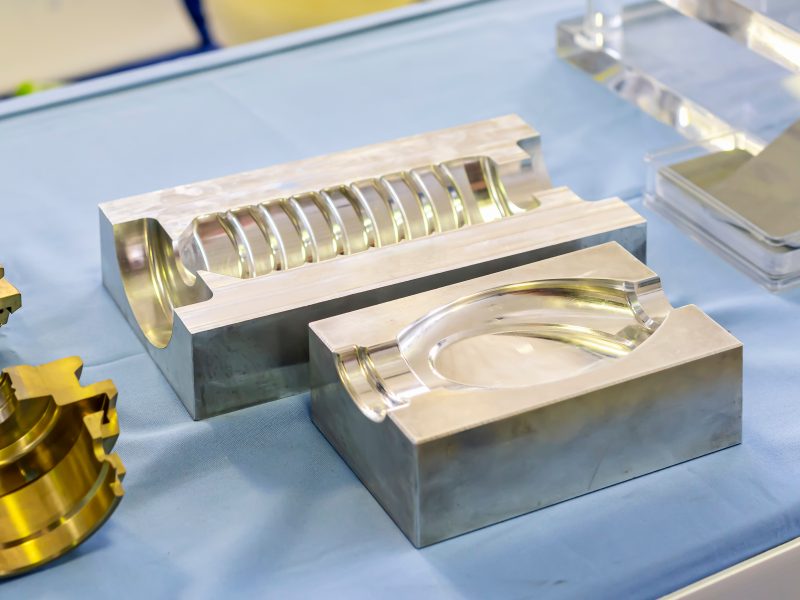

Many considerations are involved in the design of injection molding tooling. Mold design elements include frame style, material, manual vs automatic, cooling requirements, cycle times, cavitation, runner system, ejection method, and polishing and surface finish. Many customers have been conditioned to expect that the main factor in mold cost is the material… prototype aluminum molds for low volume or higher quality steel production molds for higher volume requirements. Some expect that this decision alone will drive the cost of the mold, however, many more components are involved. Mold design, material requirements, and part design all factor into determining mold cost, longevity and efficiency.

We have mold-making partners both in the US and overseas allowing us to meet widely varied requirements and budgets. When we kickoff a new project, an in-depth process of part and mold design review begins. Our team of engineers begin a “Design for Manufacturing” or “DFM” process which includes implementation of required draft angles to accommodate chosen surface finishes, gating and parting line location decisions, runner system, mold cooling elements, a mold flow analysis if desired and design of the ejection system including ejector pin locations. During this process, we do our best to point out any areas of concern that could lead to reduced mold life, including identifying thin areas of steel or unnecessary undercuts that can lead to wear on mold components and uneven wall thicknesses that cause sink marks and diminished part quality.

We work closely between the mold-maker and customer to ensure that the form and function of molded parts is optimal and the mold design is appropriate to produce parts according to established specifications. This in-depth review is part of our standard services and brings peace of mind to our customers. We greatly appreciate our customers’ trust and investment, and our team works hard to ensure the highest quality and maximum value are achieved with every project. Our team is responsive, experienced, and ready to help bring your designs to production with guidance throughout the entire process.