What Are Industrial Engineering Resins?

Industrial engineering resins refer to a category of robust polymer plastics known for their exceptional thermal and mechanical properties. These materials are engineered to outperform commodity plastics and often exhibit comparable or superior weight and strength characteristics when compared to traditional materials like wood and metals. Industrial engineering resins are favored for their versatility, making them ideal for applications requiring intricate shapes and demanding performance standards.

Molding Products With Industrial Engineering Grade Resins

At IF Associates, we understand the critical importance of delivering high-quality, durable, and reliable products to our clients across various industries. With over 40 years of experience, we have honed our expertise in molding products for both technical and commercial applications using advanced engineering resins.

Our Molding Process

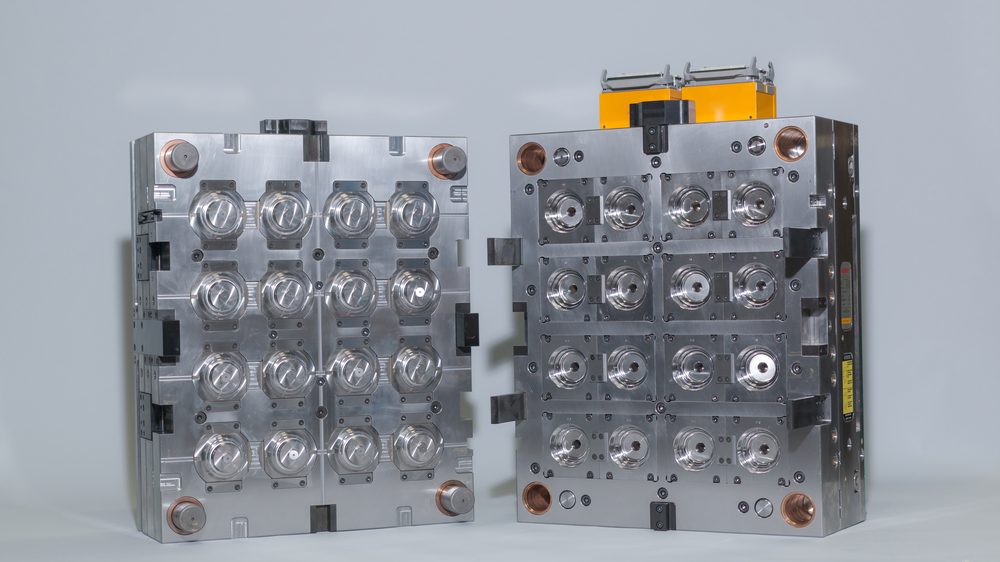

We are passionate about molding products from engineering resins for businesses of all sizes. Our streamlined process begins with the creation of molds from clients’ CAD files or drawings.

We then heat plastic pellets and inject them into the mold, ensuring complete filling. The mold is cooled, allowing the plastic to harden, resulting in products that require minimal finishing.

Why We Choose Molding Over Traditional Machining:

- Consistency and Precision: Molding enables us to create products with consistent shapes and sizes, ensuring uniformity across batches.

- Intricate Designs: The molding process allows for intricate and precise designs, meeting the unique requirements of our clients’ projects.

- Efficiency: Compared to traditional machining, molding is a faster process, enabling us to deliver products on time.

When you entrust I.F. Associates with the design, engineering, manufacturing, and assembly of your products, you can rest assured of receiving nothing less than perfection.

Our reputation, built over decades, speaks to our dedication to delivering products free from defects and meeting the highest quality assurance standards.

Producing Your Idea Into Your Product

Comparison Table: Industrial Engineering Resins

This table highlights the properties and common applications of different types of industrial engineering resins.

| Resin Type | Properties | Applications |

|---|---|---|

| Polyethylene (PE) | High impact strength, chemical resistance | Packaging, bottles, automotive components |

| Polypropylene (PP) | Heat resistance, stiffness, chemical resistance | Medical devices, food containers, pipes |

| Polyvinyl Chloride (PVC) | Fire resistance, chemical resistance | Construction, healthcare, electrical cables |

| Acrylonitrile Butadiene Styrene (ABS) | Toughness, heat resistance, machinability | Consumer electronics, automotive parts |

| Polycarbonate (PC) | Optical clarity, high impact resistance | Safety glasses, electronic components |

Diverse Clients Trust I.F. Associates

Have a Project In Mind?