What is Plastic Injection Molding?

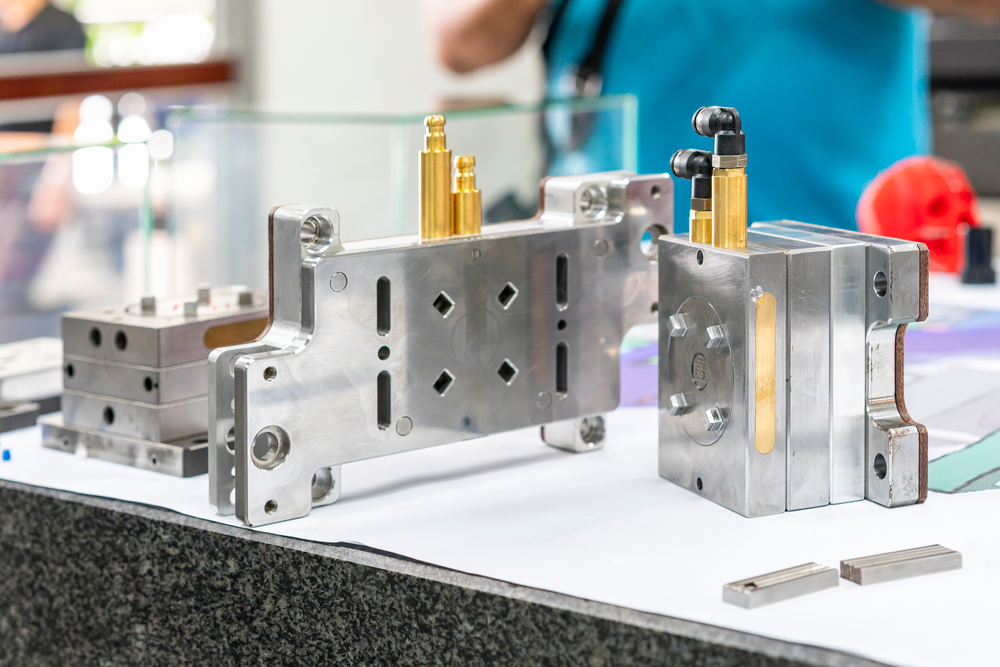

Plastic injection molding is a manufacturing process wherein molten plastic is injected into a mold cavity at high pressure and then cooled to form a solid object with a predetermined shape. This process involves several stages, including clamping, injection, cooling, and ejection.

Plastic injection molding is renowned for its versatility, allowing for the production of complex and intricate parts with high precision and repeatability. Its applications span various industries, including automotive, consumer goods, medical devices, electronics, and industrial equipment, where it is used to manufacture a wide range of components and products efficiently and cost-effectively.

Injection Molding vs

Traditional Machining

| Injection Molding | Traditional Machining |

|---|---|

| High Efficiency: Allows for mass production of identical parts | Limited Efficiency: Produces parts one at a time, leading to longer production times. |

| Complex Designs: Enables the creation of intricate shapes and designs with precision. | Limited Design Options: Machining is restricted to simpler geometries, limiting design possibilities. |

| Cost-Effectiveness: Per-unit costs decrease with larger production runs due to economies of scale. | Higher Costs: Each part requires individual machining, leading to higher per-unit costs, especially for small batches. |

| Reduced Material Waste: Material is only used where needed, minimizing waste. | More Material Waste: Machining often results in significant material waste, especially for complex parts. |

| Consistency: Produces parts with uniform quality and dimensions, ensuring reliability. | Inconsistency: Machining may lead to slight variations in dimensions and quality between parts. |

What I.F. Associates Specializes In?

Key Benefits:

We specialize in custom injection molding of both simple and complicated shapes.

By combining prototype expertise with in-depth knowledge of injection molding technology, I.F. Associates delivers several benefits:

- Critical insights leading to reduced lead times.

- Enhanced manufacturing processes.

- Early cost savings in the development phase positively impact the entire production process.

Precision Prototype Injection Molding Solutions:

- I.F. Associates provides precision prototype solutions to expedite turnaround times, minimize development costs, and validate component design and performance.

- We prioritize understanding critical features, dimensions, and product testing requirements early in the program to ensure optimal results.

- Our commitment to quality is underscored by our provision of First Article Inspection for all projects.

Prototype Injection Molding Experts

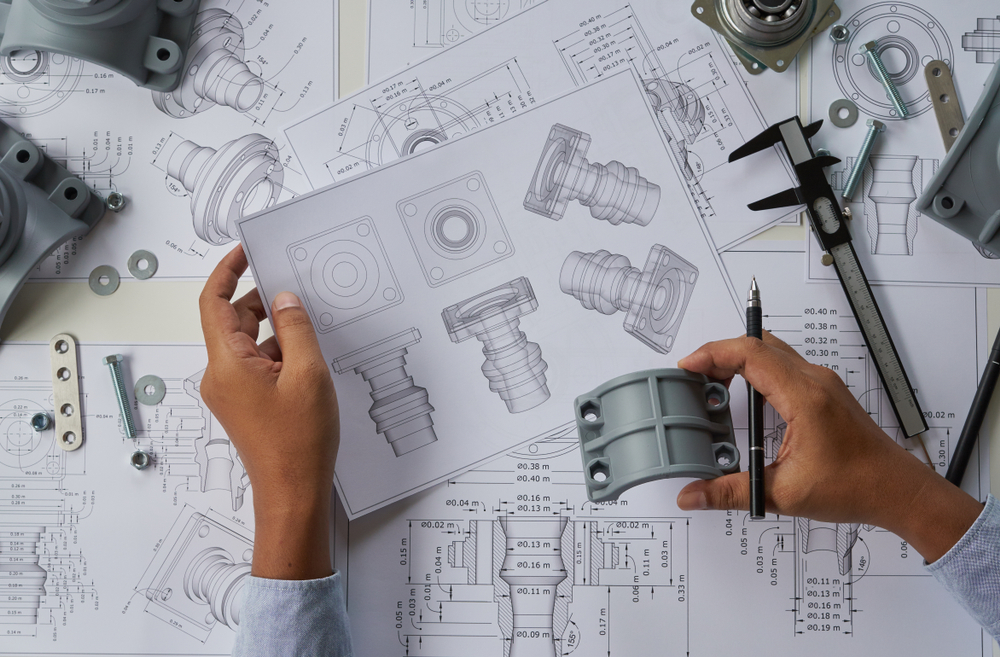

We can deliver accurate plastic injection molding of prototypes tailored to your exact specifications:

Conceptual drawings or sketches

CAD files

Conventional drawings

Our expert team can transform your vision into reality with precision and efficiency. From the initial concept to the final product, we collaborate closely with you to ensure every detail is meticulously captured and translated into a high-quality prototype. At I.F. Associates, we specialize in providing low-cost prototype tooling solutions to validate your designs efficiently.

Benefits of Prototype Molds:

- Expedited Mold Creation: We efficiently produce prototype molds in brass or aluminum to verify moldability.

- Versatile Resin Compatibility: Prototype molds can accommodate all thermoplastic resins, ensuring flexibility in material selection.

- Cost-Effective Revisions: Prototype mold revisions are simplified and cost-effective, allowing for swift design iterations.

- High Volume Production Capability: Despite being prototypes, these molds can produce large quantities of parts, facilitating comprehensive testing and evaluation.

Are you a medical professional?

If you are searching for reliable medical parts that meet stringent quality requirements, look no further.

Our range of thermoplastic and thermosetting polymer solutions upholds the highest performance and safety standards.

High-quality standards mean medical devices you can count on.

Diverse Clients Trust I.F. Associates

Have a Project In Mind?